Predictive maintenance in case of filter blockage through training of an AI

As a pioneer in the field of modern software development, we have joined forces with our Mittelstand 4.0-Kompetenzzentrum-textil-vernetzt colleagues from Hahn-Schickard in a new project to train an AI for predictive filter changes in water treatment plants.

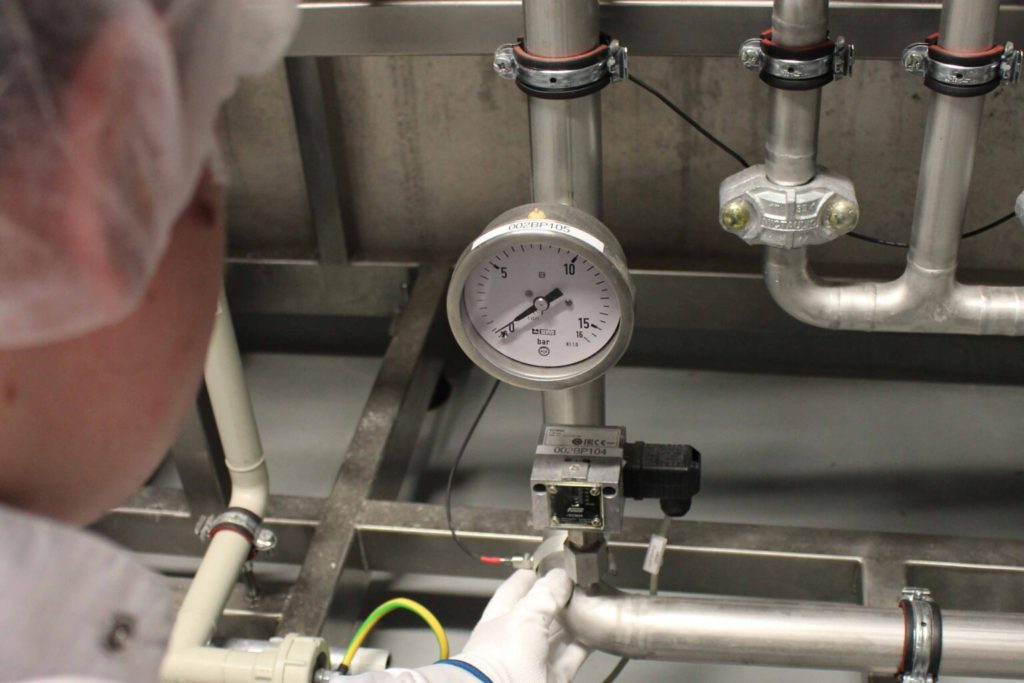

tepcon recognized early on that this reduces the productivity of the machines and has collected data from a water treatment plant over the last two years. How does it work? In a water treatment plant, water is pumped against a filter by a pump. In the process, the pump causes a vibration in the plant. In this project, among other things, the vibration data is converted into graphical images to identify vibration patterns depending on the degree of contamination of the filter. The goal is to use data from a structure-borne sound sensor attached to the pump to predict the status or life cycle of the water filter and when it will clog. In terms of predictive maintenance, a filter change will be indicated with three days' lead time in the future.

In order to get closer to the project goal of pattern recognition and, based on this, training an AI, Hahn-Schickard will use regression models from the field of machine learning and - where possible - deep learning. This is how values are created from information.